Wire Stitched Boxes

For archiving, for storage, for products...

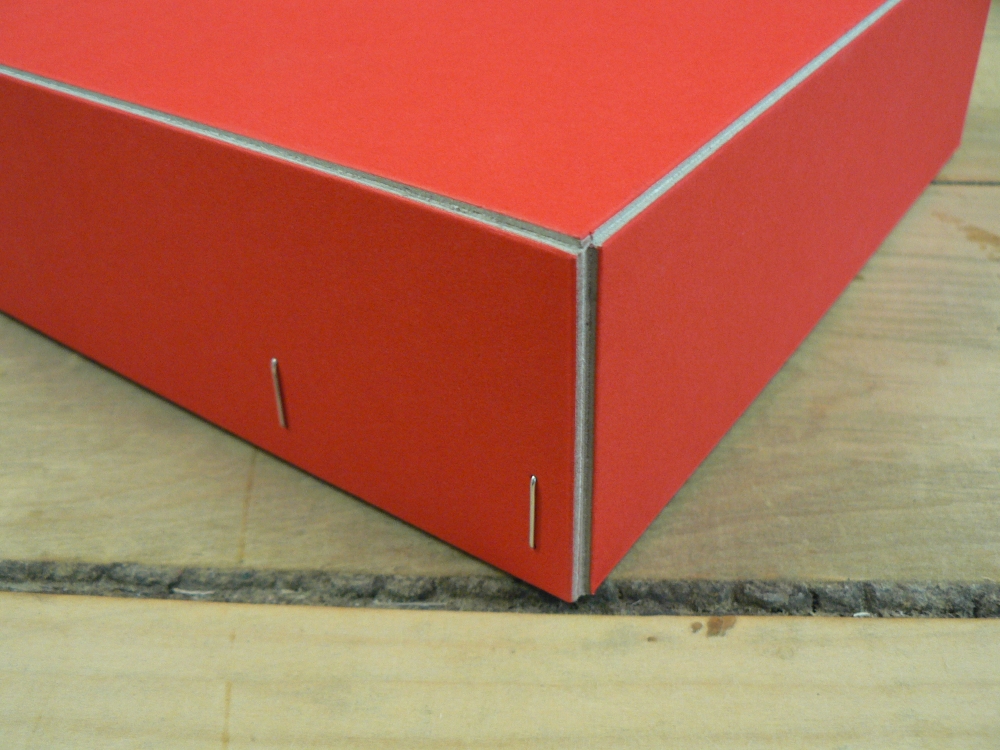

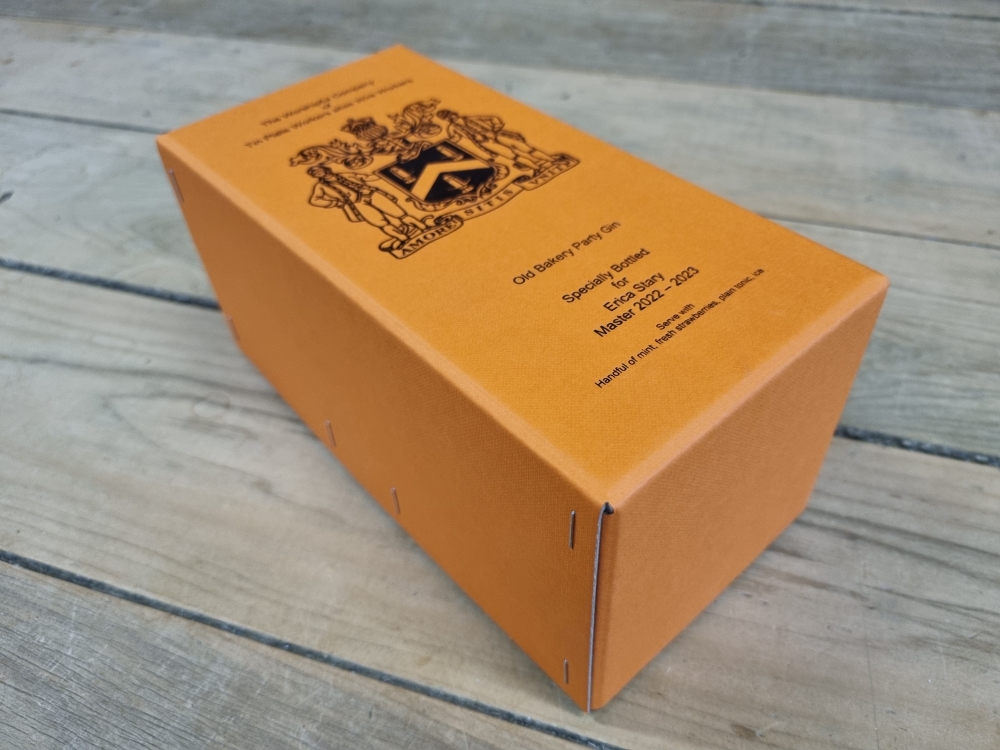

We manufacture wire stitched cardboard boxes in our London factory. They are very strong and robust so are ideal for storage, achiving and also sending items in the post. Over the last few years it has become very popular to use wire stitched packaging for products as they have a unique fashionable style. We can use our experience with presentation boxes to make your wire stitched boxes look special, whether that be with printing techniques like foiling or screen printing, or maybe using coloured cardboard or lining our standard card with coloured paper.

Handmade boxes

- Bespoke boxes made to your specification

- Handmade in our factory in London

- Can be printed easily with foil or screen printing

- Choose card between 0.75mm 1.8mm thick

- We specialise in quantities between 50 and 5000

- Typical lead time of 2 to 3 weeks from order

Archive Boxes and Storage Boxes

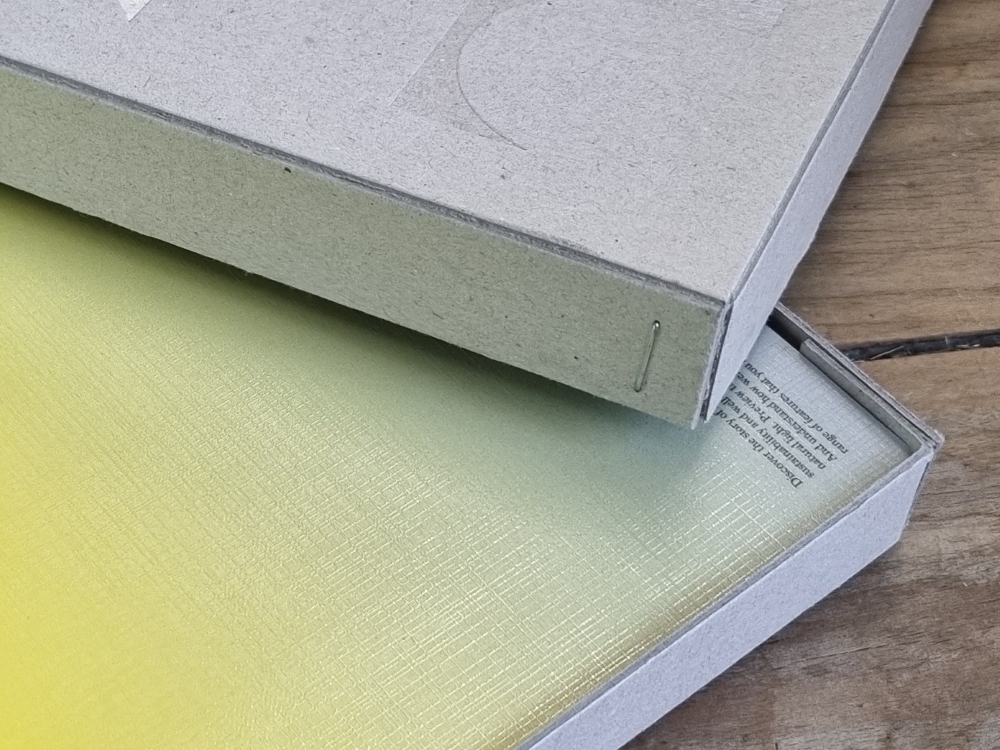

Tray & lid wire stitched boxes are as very simple style of box. The card is prepared and then it is simply folded and stapled to hold the box in shape. We have our stock card which is PH Neutral and “acid free” but if you want full archive grade board we can source that too. We can custom make these to your required dimensions using a traditional manufacturing techniques which don’t require tooling on small quantity orders.

Top Tip

Typically we use 1300 microns (1.3mm) double kraft lined card as it is strong but also easy to work with. But we do have 1.8mm kraft as well as 1.2 and 1.5mm greyboard.

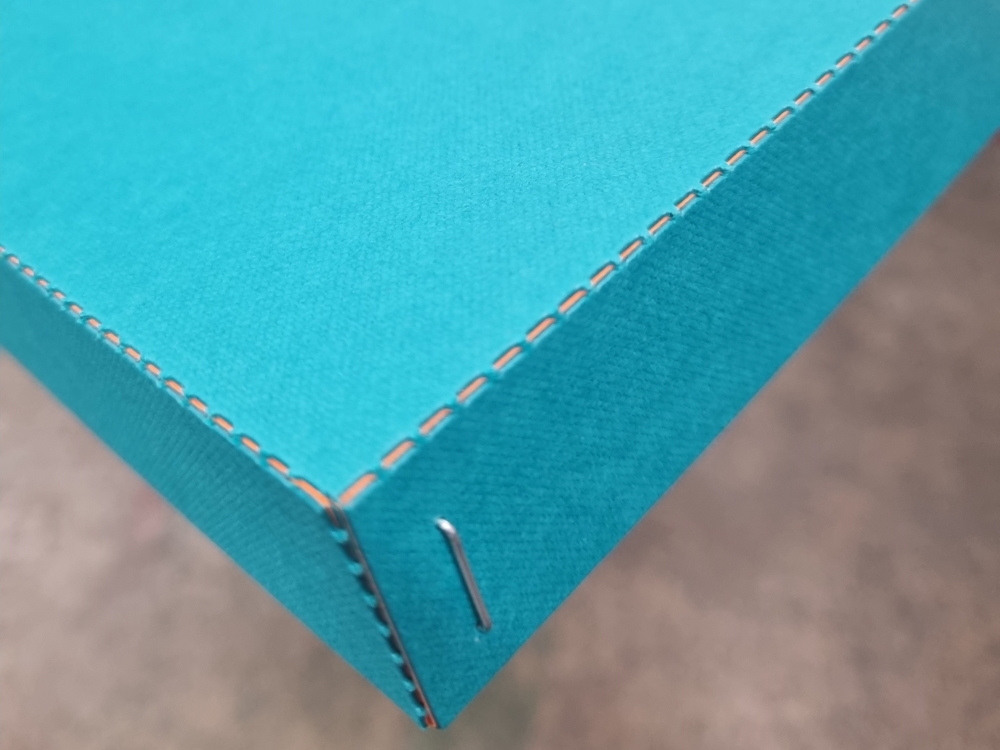

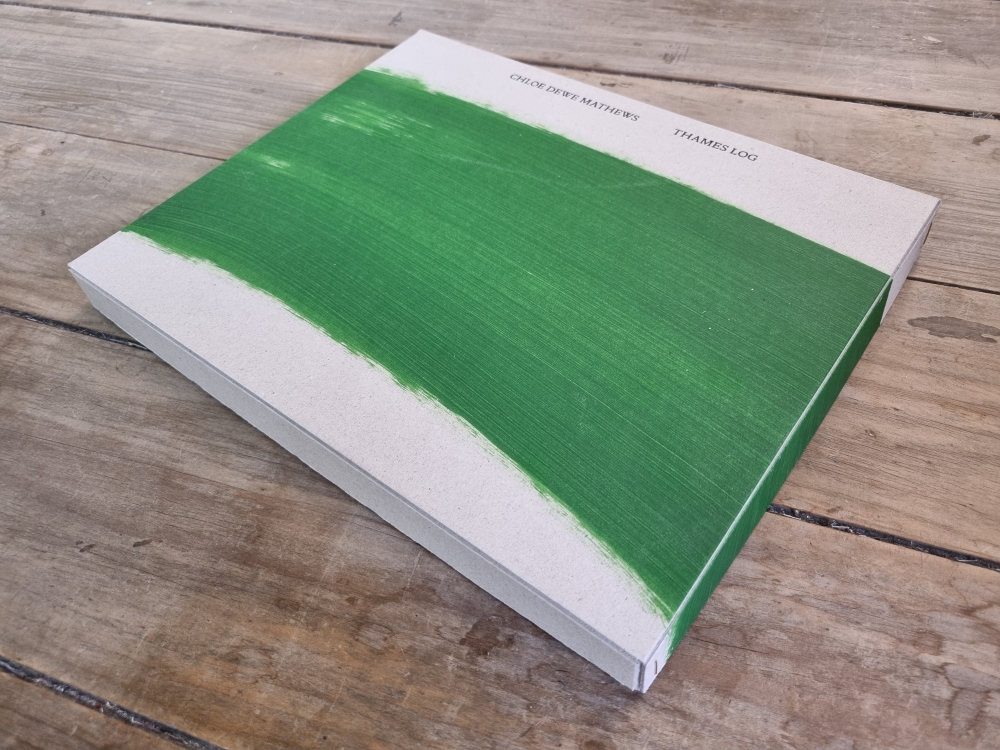

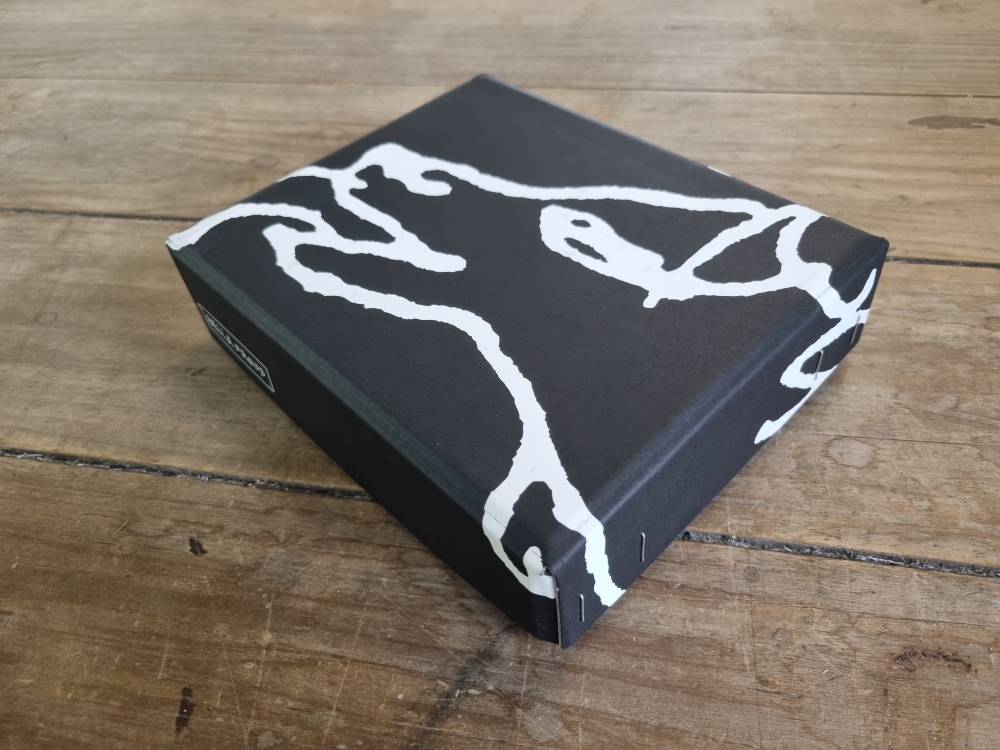

Fancy Wire Stitched Boxes

Traditonally wire stitched boxes were just for practical industrial type use. However in recent years it has become fashionable to make wire stitched boxes that also look great. We can use our experience in paper over board presentation boxes to apply print in the form of screen printing or hot foil to our stock materials. Or we can also use more premium card material and even apply paper to the card when its flat. You still get a strong yet simple box but it can look great too. There are still raw edges of card and staples but that helps give this style of packaging a real unique look as it is comparitively rarely used.

Top Tip

Our stock kraft and grey card is a really good value material. It is strong, durable and perfectly in keeping with the style. More premium cards can be used to create stunning packaging

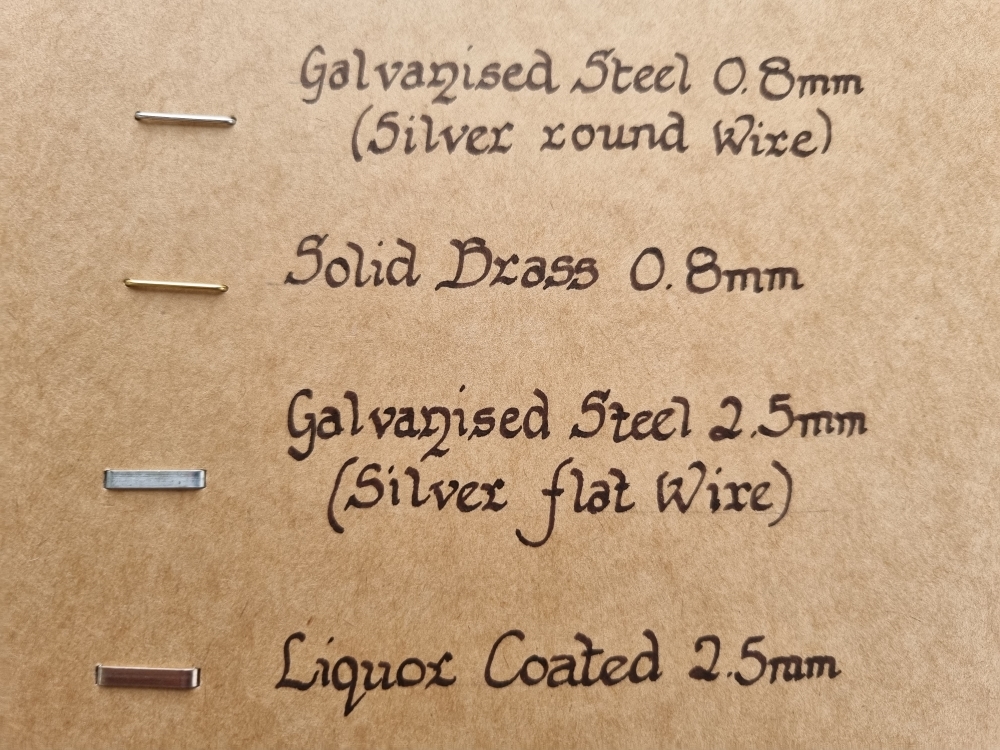

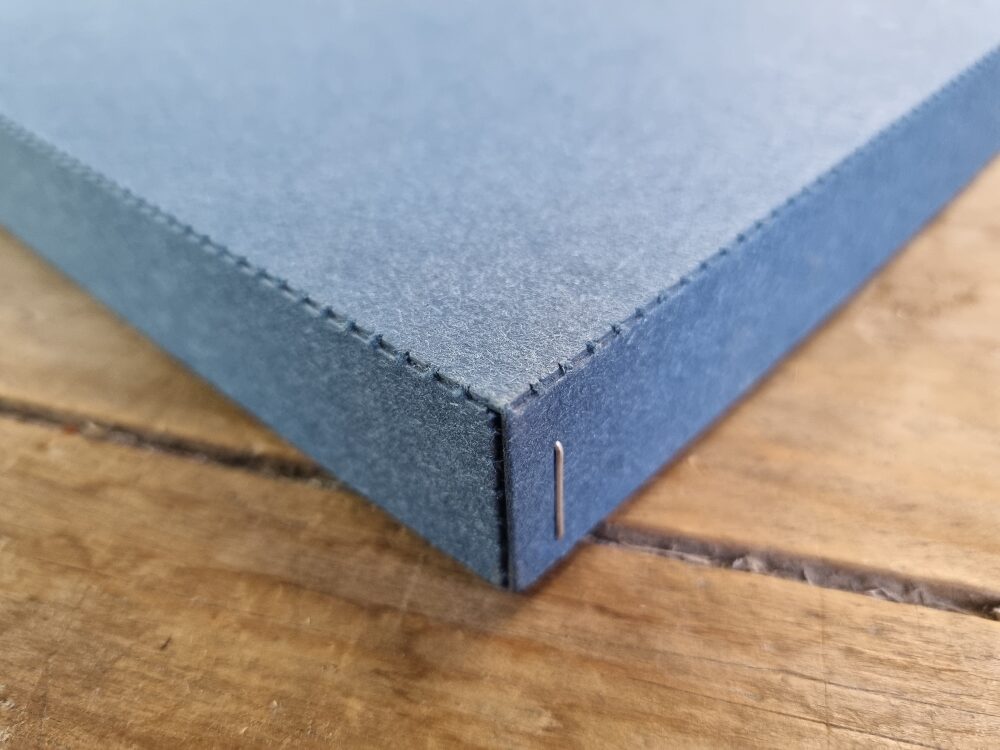

Choices of Stitches and Folds

We have a choice of stitches and folding techniques which you will need to be aware of. We have 4 types or wire:

- 0.8mm round galvanised

- 0.8mm round brass wire

- 2.5mm flat galvanised

- 2.5mm flat dusty copper

With the folds of the box we mainly do creased folds as this is the strongest and simplest way. We don’t need tooling to achieve this as we have rotary bending machines which we can adjust to the correct depth of box. We can do scored folds which is where the material is cut most of the way through and then the card can fold. It gives a cleaner, sharper edged look but you see the raw edge of the card and the card is weakened. We can also do a perforated score on thinner materials, this gives a cleaner fold like a score but some material is left so the material isnt weakened as much.

- Creased folds – strongest and cheapest on smaller quantities as no tooling required

- Scored folds – cleaner lines but weaker and requires tooling

- Perforated score – suitable for thinner materials, medium strength and requires tooling

Top Tip

Creases on thicker material need to be wider so the folds are more rounded. This makes the boxes look more rounded. Thinner creases on thinner material can look neater and cleaner.